Practical applications of CO2 threshold control

*Aquatic Seedlings Cultivation Application

A 40m3 closed room for cultivating aquatic seedlings is used as landscape in aquatic aquariums.

With current technology, most users use CO2 solution or CO2 smoke soaked in water.

This is the step of cultivating seedlings to adjust stable CO2 level for grasses and plants living in water before breeding and widely distributing to the market.

* Italian Lettuce Seedling Cultivation Application

The greenhouse grows purple lettuce, a vegetable variety imported from Italy, grown to sell high-quality clean food.

*Carrot and potato storage in Don Duong, Lam Dong. This application does not activate the illumination sensor function but only uses a fixed setpoint for 3 fixed parameters for the entire control program.

Monitoring Parameters and Data Storage

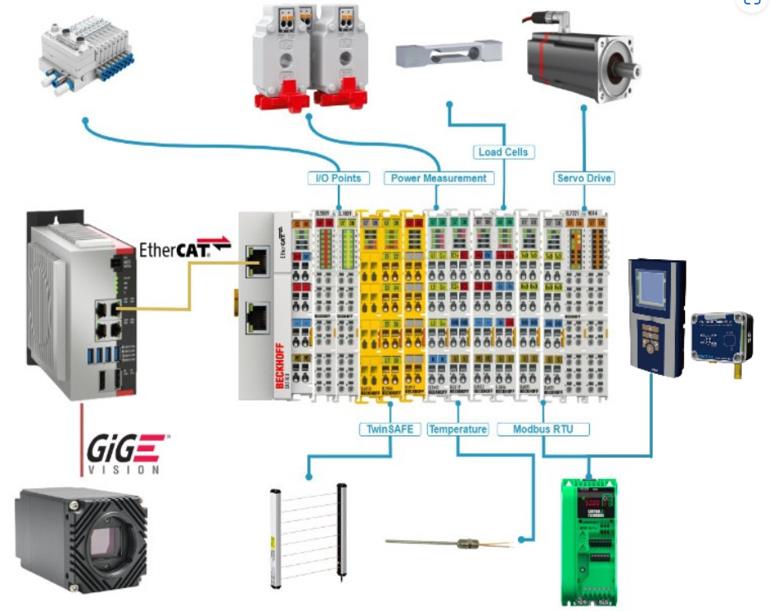

Example: Smart monitoring and storage solution package combined: CO2, temperature, humidity Sensor FOX-8STC, FS-600R (Conotec), Control Techniques Inverter, IPC Industrial PC (Beckhoff)…

The Industrial PC (IPC) monitors and collects data from peripheral devices:

- Inverter

- Sensor: Safety sensor, temperature sensor, humidity sensor, CO2 sensor

- Valve: The opening and closing status of the valve

- Measuring current, voltage, energy consumption of motors, machinery…

- Vision camera to monitor and inspect product quality

- HAN MY VIET Ho Chi Minh City

Address: 203 - 205 Nguyen Thai Binh St., Nguyen Thai Binh Ward, Dist. 1, HCM City.

Phone: (028) 3821 6710 – 091 621 6710

Mail: hmv@hanmyviet.com

+ HAN MY VIET Ha Noi Branch

Address: 72 Bui Ngoc Duong St., Bach Mai Ward, Hai Ba Trung Dist., Ha Noi

Phone: Ms. Hiện 098.699.1948

+ HAN MY VIET Bac Ninh Branch

Address: 6 Ngoc Han Cong Chua St., Hoa Dinh Quarter, Vo Cuong Ward, Bac Ninh.

Phone: Mr. Tiến 097.546.0366

+ HAN MY VIET Da Nang Branch

Address: 26 Tang Bat Ho St., Hai Chau II Ward, Hai Chau Dist., Da Nang.

Phone: Ms Hoa 033.636.3965

+ Ho Chi Minh City District 5 Branch

HUNG PHU AUTOMATION TECHNOLOGY CO., LTD

Address: 27 Trieu Quang Phuc, Ward 10, Dist. 5, HCM City.

Phone: 190 063 3459 – (028) 7300 3459

+ Binh Duong Branch

HUNG VIET AUTOMATION ELECTRIC CO., LTD

Address: 1/3 Binh Duc 2 Quarter, Binh Hoa Ward, Thuan An City, Binh Duong Province

Phone: (0274) 363 6508 – 090 310 8416

+ Dong Nai Branch

HOP KHANG AUTOMATION CO., LTD

Address: 76/1 Pham Van Thuan, Quarter 1, Binh Da Ward, Bien Hoa City, Dong Nai

Phone: (0251) 6290 790 – 3813 305